Key Specifications / Features

Model No.: HM-231028-ADM-03 Hits: 0

Our double-layer enclosure leak-proof adult diaper machinery is engineered with advanced features. It incorporates dual-frequency conversion control for optimal performance and offers easy operation through the human-machine interface. With a production speed of 300 pieces per minute, it ensures efficient and precise manufacturing of adult diapers while maintaining leak-proof reliability.

Request a quoteTags

Detail Information

Double Layer Enclosure Leak Proof Adult Diaper Machinery

| Overall Size | 33M*8M*4.5M |

| Machine Size | 31M*2.2M*4.5M |

| Design Speed | 300pcs/min |

| Stable Work Speed | 180(Auto)-250(Full sero)pcs/min |

| Product Yield | ≥97% |

| Powere Source | 380V, 50HZ |

| Machine Capacity | About 400KW |

| Air Pressure | 0.6-0.8Mpa |

| Machine Weight | About 105T |

Feature

1. Automatic packaging design and special machine for trial packaging of diapers, diapers, sanitary napkins and other sanitary products.

2. Dual frequency conversion control, the bag length is set and cut immediately, and there is no need to adjust the empty walk. It is in place in one step, saving time and film.

3. Human machine interface, convenient and fast parameter setting.

4. Fault self diagnosis function, and the fault display is clear at a glance.

5. High sensitivity photoelectric eye color mark tracking and digital input of sealing and cutting position to make the sealing and cutting position more accurate.

6. Independent PID control of temperature, better suitable for various packaging materials.

7. Positioning shutdown function, no knife sticking and no waste of coating.

8. The transmission system is simple, the work is more reliable and the maintenance is more convenient.

9. All controls are realized by software to facilitate function adjustment and technical upgrading and avoid backwardness.

Control Parts

The main machine controlled by PLC and shown by touch screen.

Heating controlled in touch screen

Setting the heatting time, punch time and white / printed bags in the PLC.

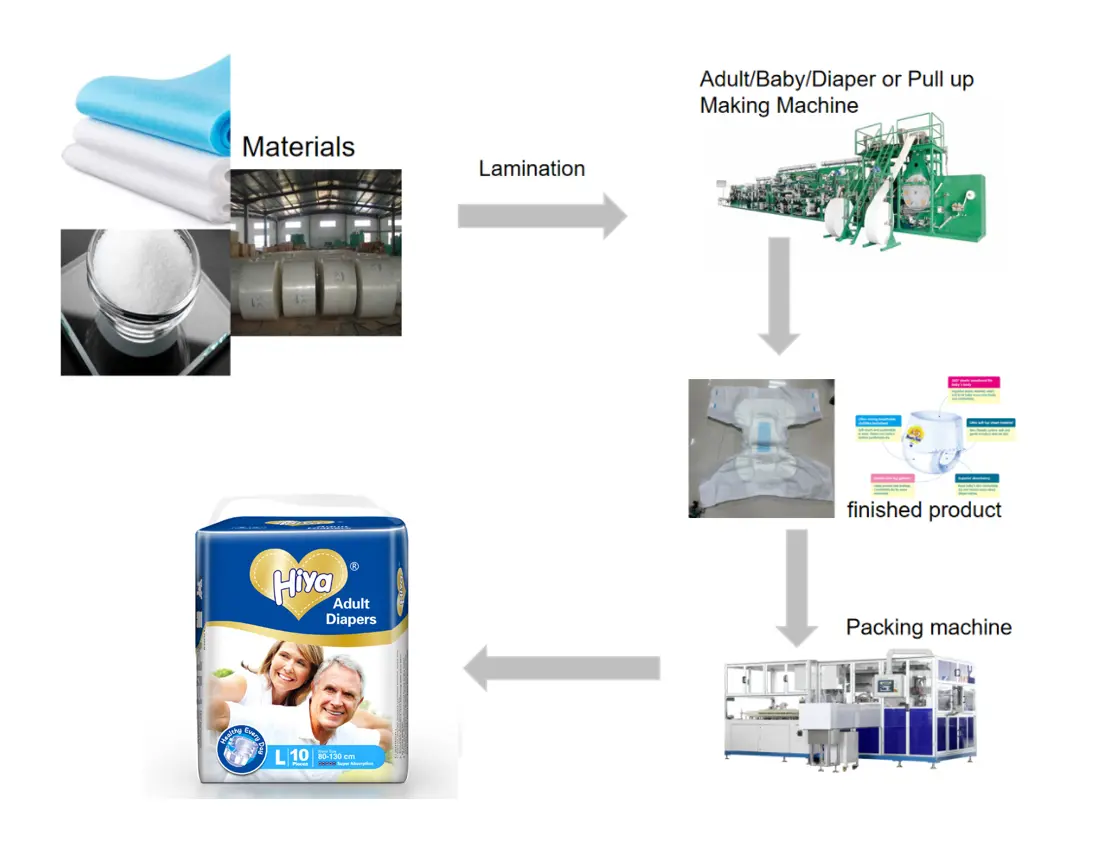

Production Process

Machine Draft