Key Specifications / Features

Model No.: HM-231018-SNM-03 Hits: 2

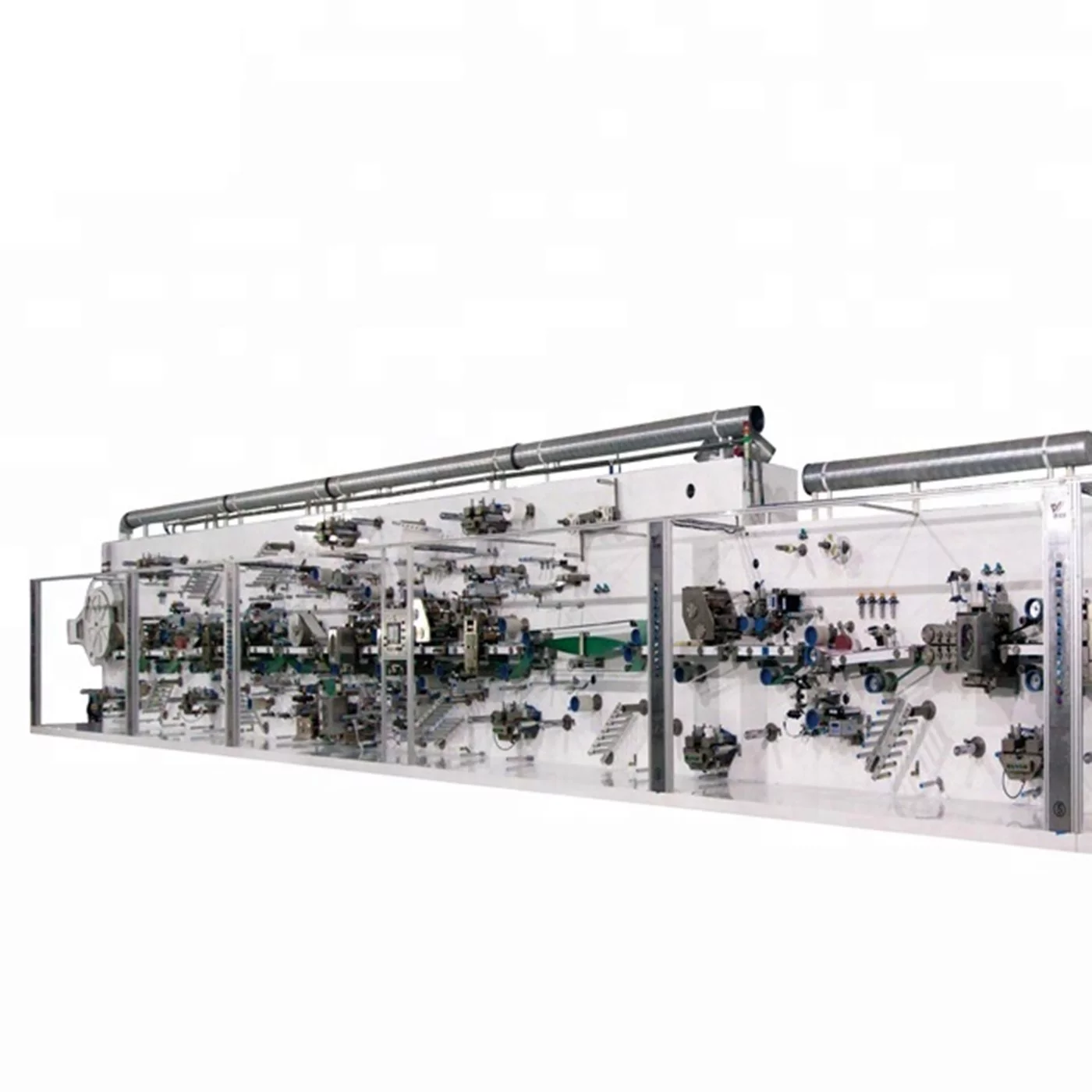

Crafted for perfection, our Ultra Thin Sanitary Napkin Making Machines offer full servo precision. These machines operate at an impressive speed of 700 pieces per minute and come equipped with the cutting-edge Germany BST Automatic Web Guide System, as well as essential safety features for optimal performance.

Request a quoteTags

Detail Information

Fully Automatic Ultra Thin Sanitary Napkin Making Machines

| Subject | Parameter |

| Stable Working Speed | 300-700pcs/min (By order) |

| Pass Percentage | ≥98% |

| Operating Rate | ≥85% |

| Power Supply | 380V 50Hz |

| Electrical Supply | 380V ±5%, 50Hz Three-phase four-wire + ground wire |

| Power Installed | About 180KW (Not included hot melt glue machine) |

| Supply Pressure | 0.6-0.8Mpa |

| Machine Sizes (L× W× H ) | 22.0m× 5.5m× 3.5m(L× W× H )(Only for reference) |

| Main Engine Sizes (L× W× H ) | 32m× 9.0 5.0m (L× W× H ) ( Only for reference) |

| Machine Color | Customerized |

Configuration:

| Configuration | |

| Product Structure | Carrier Tissue, Fluff Core (Mix with SAP), Topsheet(3-PCS structure), ADL, Backsheet, Back Release Paper, Wings Release Paper, Pouch Film |

| Product Size | Daytime use: 240mm Night use: 285mm (Customized Design) |

| Control System | PLC Programming control, HMI operation |

| Tension System | Carrier tissue, absorbent paper, topsheet N.W., leg cuffs N.W., ADL, PE film, Back release paper, Wings Release Paper, pouch film A&B shaft active unwinding by inverter motor |

| Drive System | Full servo drive. Using import conveyor and timing belt. Important Part using import bearing. |

| Safety System | Safety guard installed at the operating side, equipped with emergance stop switch, security identifier. Driven side is equipped with safety pull wire |

| Materials corrective system | Germany BST automatic web guide system (optional) |