As a typical absorbent hygiene product, diapers have higher production materials and manufacturing processes than general tissue paper, resulting in higher profit margins. In recent years, adult diapers, aimed at improving the quality of life for the elderly and disabled individuals, have seen a significant increase in global sales, indicating a promising future for diaper making machine.

In the baby diaper sector, with increased per capita purchasing power and evolving parenting concepts, the market has maintained a rapid growth momentum. The vast global population provides growth opportunities for the baby diaper market, expected to continue over the next five years. Currently, over 90% of infants aged 0 to 2 in major urban areas have used disposable diapers, and the market for affordable disposable diapers is gradually expanding in smaller towns and relatively affluent rural areas.

Regarding adult incontinence products, the industry has entered a period of rapid growth in recent years due to changes in the domestic population structure. Market sizes in multiple countries have exceeded billions, and with an average global penetration rate of 12%, further development is anticipated as the economy grows, society ages, and consumer perceptions of elderly individuals change, despite the initially low user base.

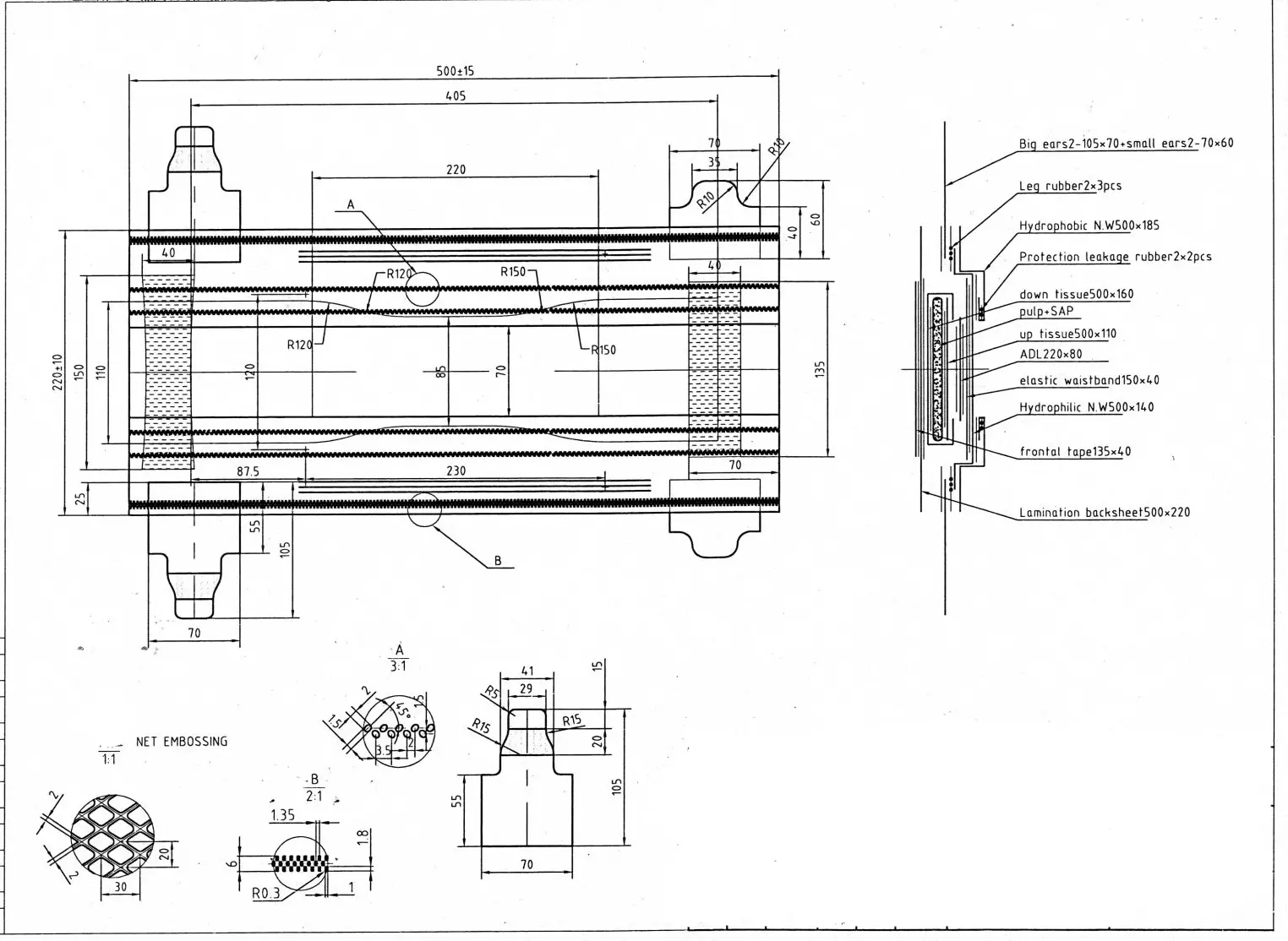

Layer by Layer Analysis:

Topsheet Directly in contact with the baby's delicate skin, the top layer demands softness and breathability, not absorbing water itself but maintaining the baby's body's dryness. The material used for the top layer is non-woven fabric, with hot air non-woven fabric and spunbond non-woven fabric being the most commonly used in the diaper industry. Hot air non-woven fabric is preferred for its superior performance.

Distribution Layer Located between the top layer and the absorbent core, the distribution layer ensures fast, efficient, and uniform absorption of liquids. Fibers in the distribution layer are mainly arranged longitudinally, allowing quick liquid absorption and diffusion to prevent local blockage in the absorbent core.

Absorbent Core Diapers on the market usually come in two core structures: full-core and composite paper core. The composite core consists of fluff pulp and superabsorbent polymer (SAP). SAP, a crosslinked polymer with a three-dimensional spatial network, exhibits remarkable water absorption and retention properties. It is widely used in sanitary products, such as diapers, due to its exceptional absorbency, gel-forming ability, and stability under various conditions.

Backsheet Appearing as a plastic film, the bottom film is actually a breathable microporous film. Microscopic pores, crucial for breathability while preventing water penetration, ensure proper ventilation.

Leg Cuffs for Leak Prevention Located on both sides of the thigh openings, connecting to the top layer, leg cuffs prevent urine from leaking out due to delayed drainage.

In conclusion, although a diaper may seem simple, it incorporates advanced technologies. The production process ensures that all qualified raw materials used are safe and environmentally friendly for both users and the environment.