1. Continuous composite materials: generally there are tissue paper, air-laid paper, top sheet, bottom film, pouch film.

2. Short-cut or circumferential cut composite materials: generally there are water-absorbent paper, ADL, central release paper, wing release paper, and easy tear tips. After cutting through the fixed-length conveying, it is combined with other materials.

II Sanitary napkin materials by the mechanic process

1. shaft-driven mechanical unwinding process.

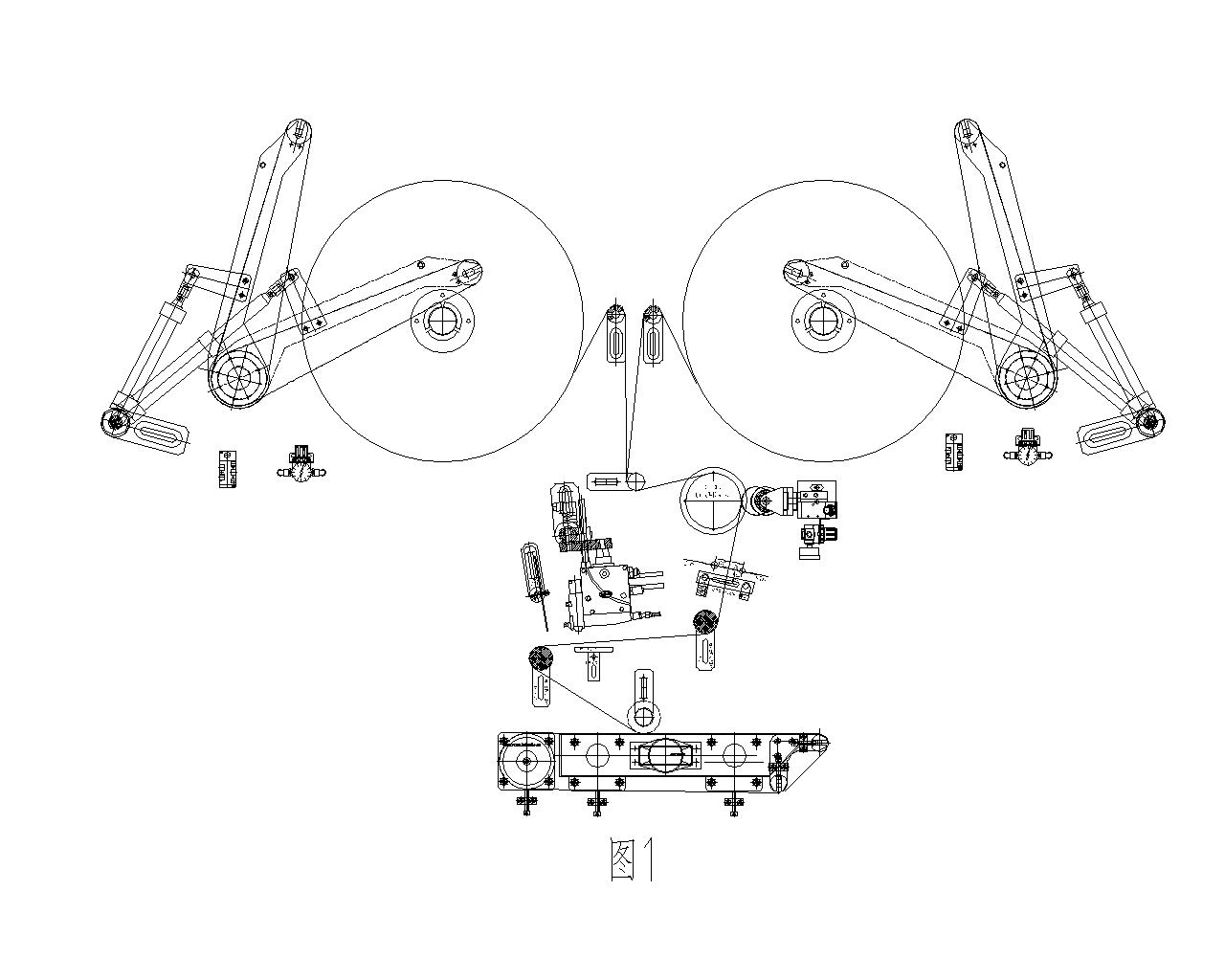

1.1 Continuous composite flow chart: see Figure 1

driven unwinding → belt feeding → traction→ glue spraying → lamination

The above process corresponds to mechanical parts:

Driven unwinding assembly → belt feeding assembly → material traction pulley assembly → glue gun, of which 6-7 sets of material transition wheels.

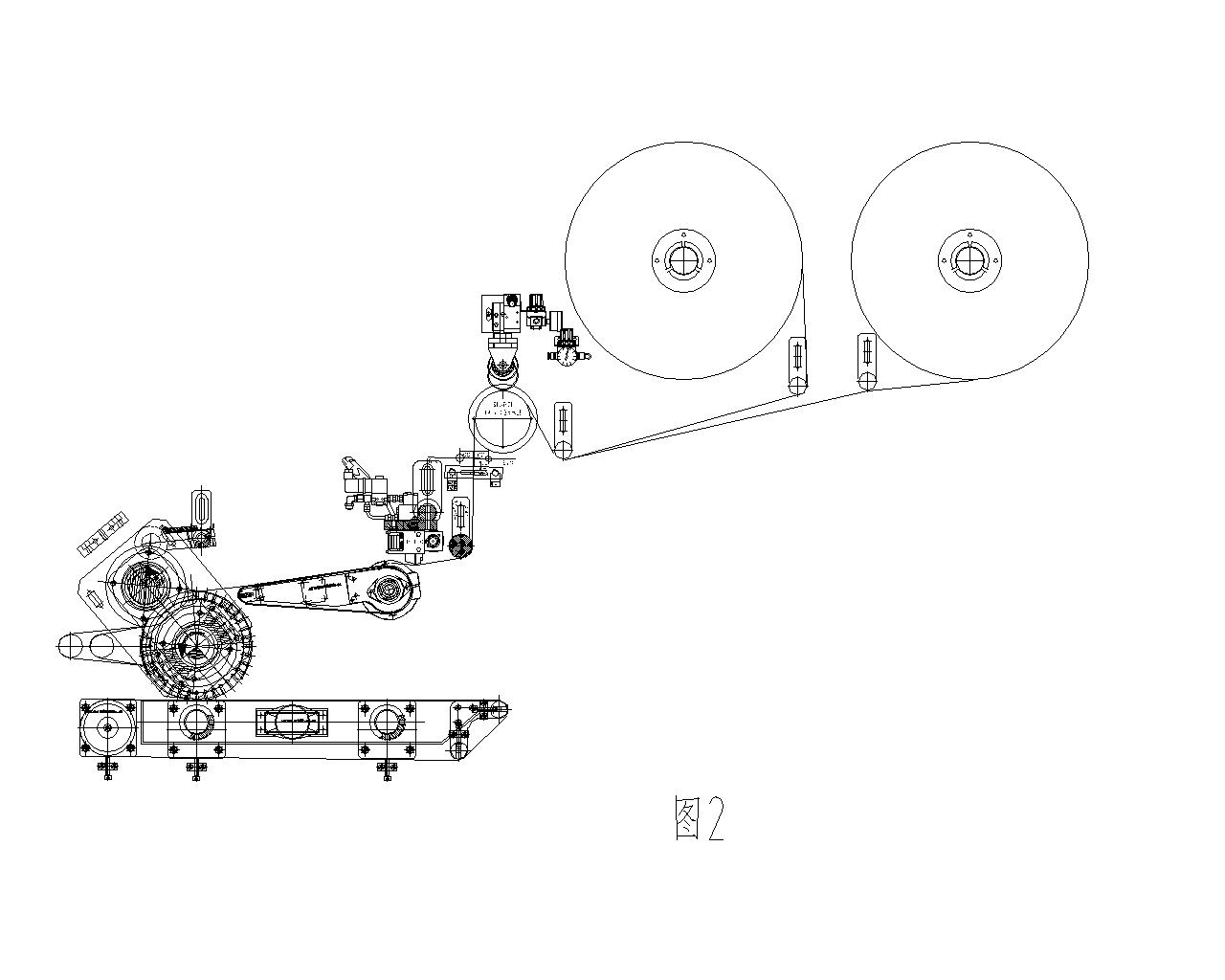

1.2 Composite material flow after short or circumferential cutting: see Figure 2

driven unwinding → (traction) → traction(fixed length) → glue spraying → conveying → cutting → transferring lamination

The above process corresponds to mechanical parts.

Driven unwinding assembly, belt feeding assembly, material traction assembly, traction (fixed length), glue gun, feeding suction box assembly, shortcutting assembly, of which 5-6 sets of material transition wheels.

2. The main shaft driving inverter unwinding process.

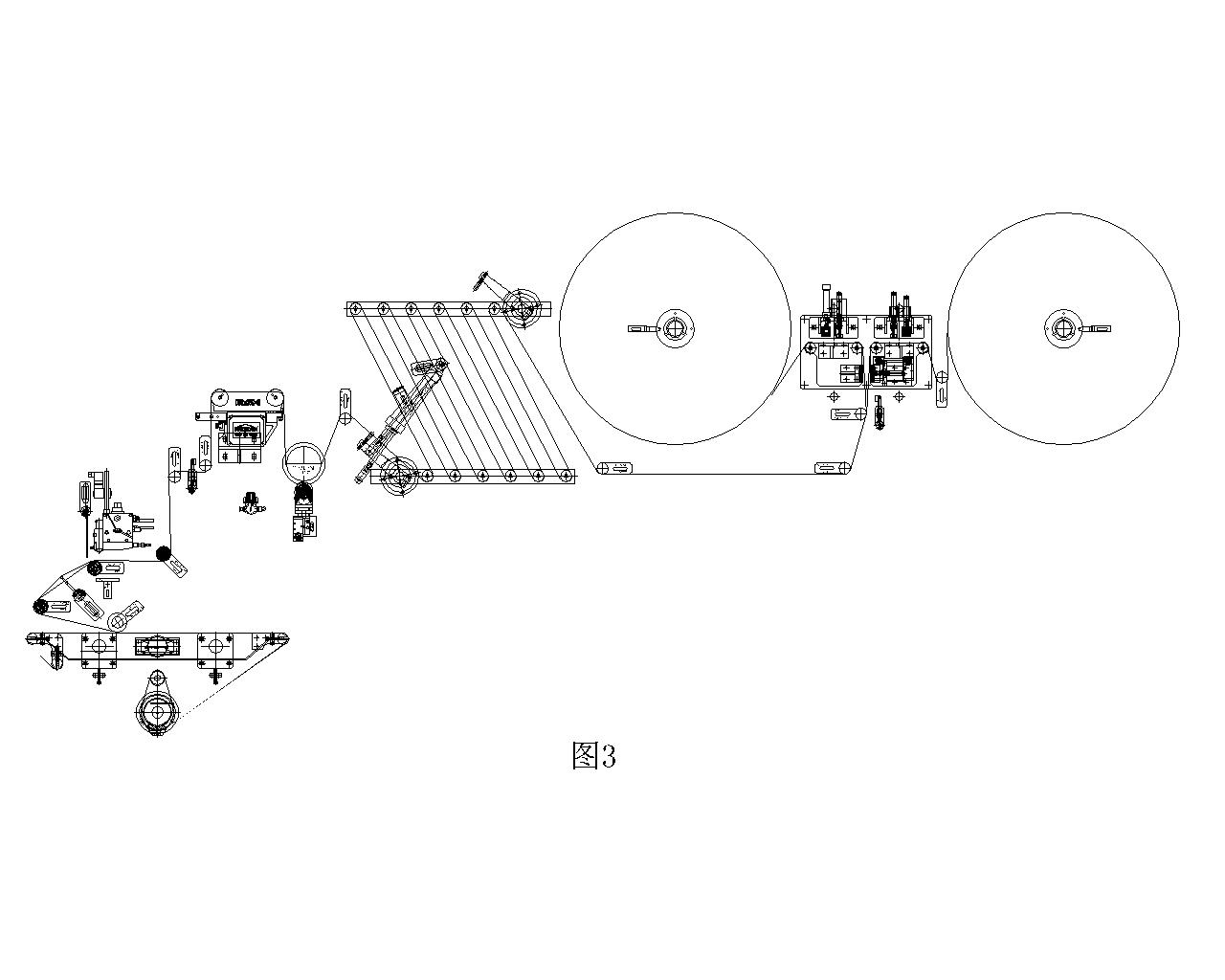

2.1 Continuous composite materials flow: see Figure 3

Three-phase asynchronous motor unwinding→splicing and cutting materials→storing materials→traction(main shaft)→web guiding→spraying (scraping)glue→laminating.

The above process corresponds to mechanical parts:

Air shaft assembly, splicing assembly, double pendulum tension control assembly, material pulling wheel assembly, web guider, glue gun, of which 10-11 sets of material transition wheels

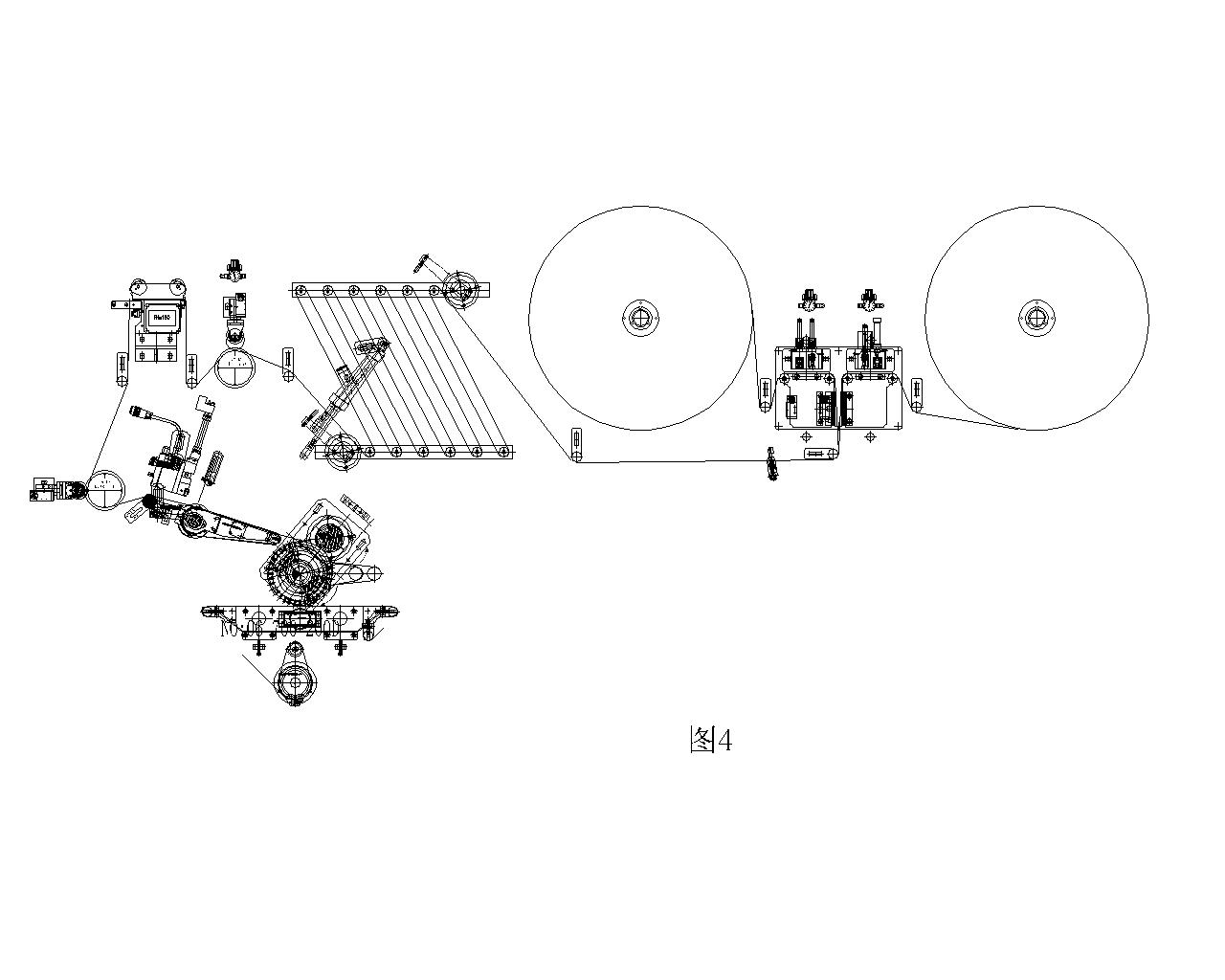

2.2 Composite material flow after short or circumferential cutting: see Figure 4

Air shaft (three-phase asynchronous motor) →Splicing and Cutting →Storage rack →Traction→Web guiding→Traction(fixed length) →Glue spraying →Conveying→Cutting →Transfer and lamination

The above process corresponds to mechanical parts:

Air shaft assembly, splicing assembly, double pendulum tension assembly, material traction roller assembly, web guide, glue gun, material traction assembly, suction box assembly, shortcutting assembly, of which 8-10 sets of material transition wheels