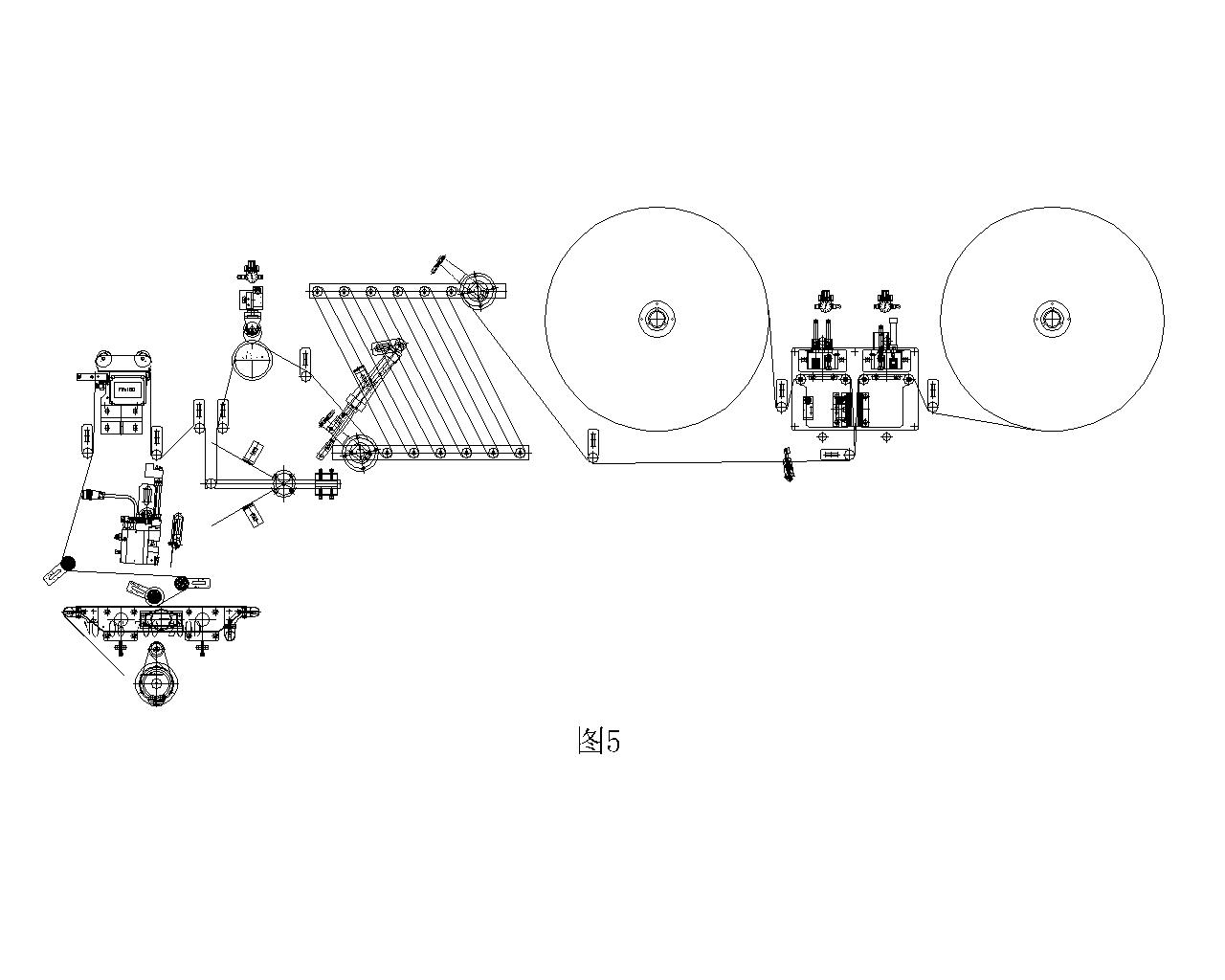

3.1 Continuous composite flow: see Figure 5

Inverter uncoiling→Cutting→Storage rack→Hauling→Secondary tension control→Skewing→Glue spraying→Laminating

The above process corresponds to mechanical parts.

Air expansion unit, splice unit, double pendulum tension control unit, material pulling pulley unit, secondary tension control unit, deflector, and Glue gun. Of which 10-12 sets of material transition wheels

Note: 1 set each of traction and secondary tension control has been added to the external material mechanical assembly; 1 set of 90° angle assembly has been added; 1 motor has been added.

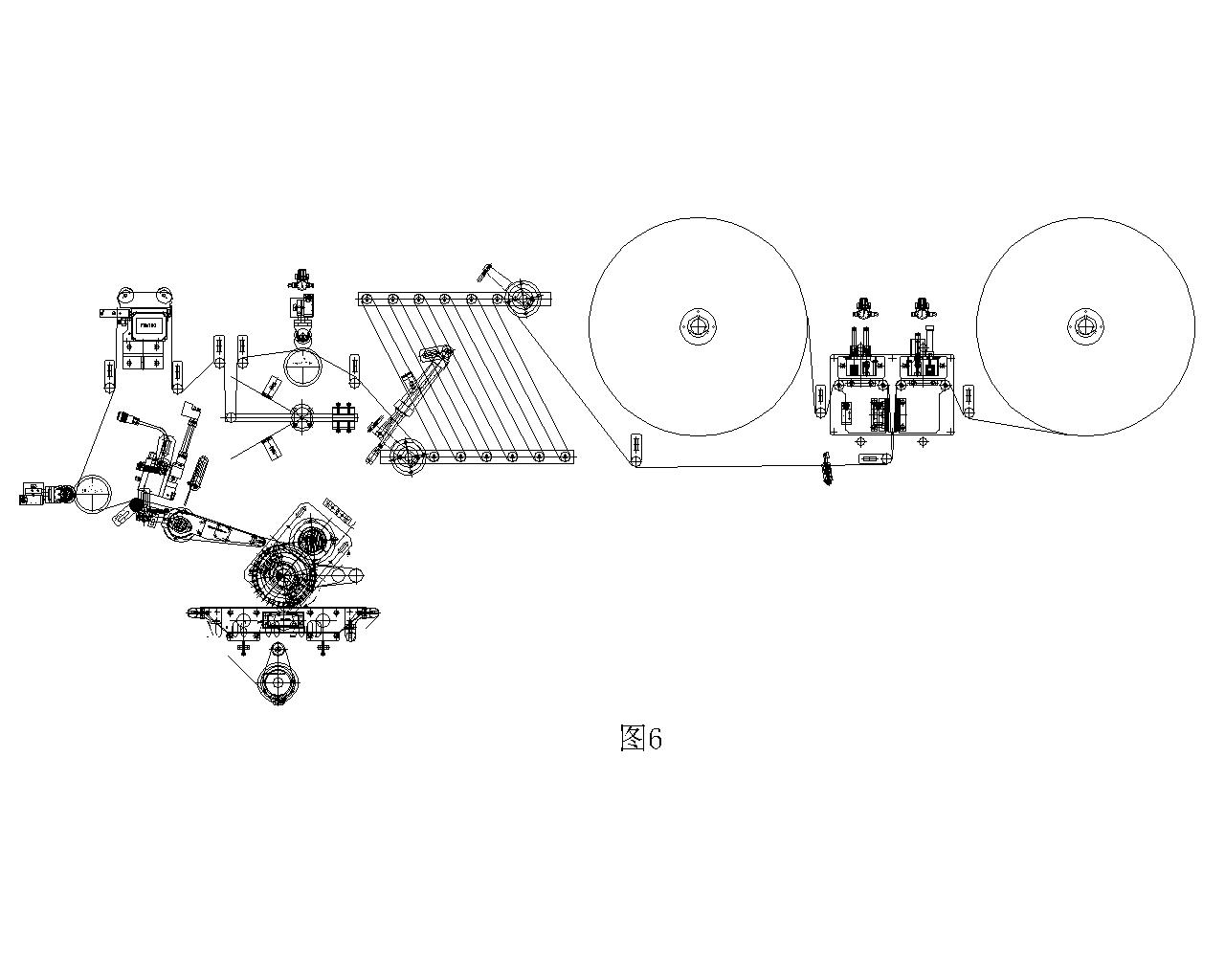

Short-cut composite material process: see Figure 6

Inverter uncoiling→Cutting→Storage rack→Hauling→Secondary tension control→Deflection→Hauling→Glueing→Conveyance→Transfer lamination

The above process corresponds to mechanical parts.

Air expansion unit, splice unit, double pendulum tension control unit, material pulling pulley unit, secondary tension control unit, deflector, and Glue gun, material pull wheel assembly, feed suction box assembly, short cutter assembly. Of which 10-12 sets of material transition wheels